Media

No more laundry?

Innovative and ideal liquid-repellent surfaces developed by HKU scientists could make the dream come true!

14 Nov 2017

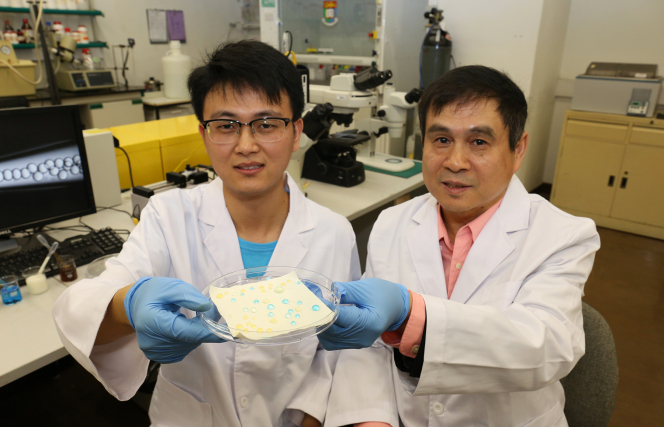

Professor Wang Liqiu (right) and Dr Zhu Pingan from HKU Mechanical Engineering Department showcase the liquid repellent material they innovated.

On liquid-repellent surfaces, liquid droplets bounce away instead of being stuck. These surfaces are important in many fields, such as water-repellent clothes and anti-fouling kitchenware. Used as drag-reduction coatings for water vehicles, these surfaces can even help with speeding up cargo ships and military equipment so as to save energy. The dream of research and development on liquid-repellents is a structure that has robust liquid repellency, strong mechanical stability, and is inexpensive to produce on a commercial scale. However, the functional outcomes of existing liquid-repellent surfaces have not been satisfactory, because of inadequacies of conventional structural design and fabrication approaches in engineering microstructures and properties of such surfaces.

The challenge was recently overcome by breakthrough research led by Professor Wang Liqiu at the Department of Mechanical Engineering, Faculty of Engineering, the University of Hong Kong (HKU) through the development of a robust liquid-repellent structure and the fabrication of porous surfaces by an innovative microfluidic-droplet-based technique. Materials such as textiles, metals, and glasses covered by a layer of this robust porous surface can then become liquid-repellent. The paper was recently published in academic journal Nature Communications (Zhu P. A., Kong T. T., Tang X. and Wang L. Q. 2017. Well-defined porous membranes for robust omniphobic surfaces via microfluidic emulsion templating, Nature Communications 8, 15823). With the new technology developed by the team, clothes would never get wet on rainy days in the future.

The team resolves effectively the conflict between liquid-repellency and mechanical stability by the springtail-cuticle-inspired design of liquid-repellent structures. Springtails are soil-dwelling arthropods whose habitats often experience rain and flooding. As a consequence, springtails evolve their cuticles with strong mechanical durability and robust liquid repellency to resist friction from soil particles and to survive in watery environments, respectively. Inspired by springtail cuticles, the research team designed porous surfaces composed of interconnected honeycomb-like micro-cavities with a re-entrant profile: interconnectivity ensures mechanical stability and re-entrant structure yields robust liquid-repellency.

Figure 1 Soil-dwelling springtails with dew (body length: ~2.5 mm).

(Source: https://www.flickr.com/photos/lordv/302831402/in/album-72157594371411831/).

*For the press using this photo, please credit Brian Valentine.

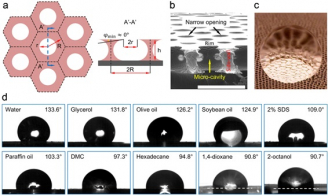

Figure 2 Bio-inspired design of liquid-repellent structures with robust liquid-repellency.

Schematic (a) and image (b) of the designed porous surface. (c) Photo of a water drop suspended on top of the porous surface. (d) repellency of 10 different liquids by the porous surface.

Robust liquid-repellent structure shows a 21-fold enhancement in mechanical stability

The robust liquid-repellent surfaces repel at least 10 types of liquid, including water, surfactant solutions, oils, and organic solvents (Figure 2d) and show an astounding over 21-fold enhancement in mechanical stability compared with discrete structures (Figure 3). The porous surfaces are capable of recovering their non-wetting state as well even if micro-cavities are partially wetted by water. The flexible surfaces can also be readily coated onto various objects for liquid-repellency.

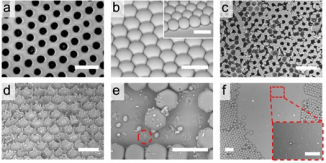

Figure 3 Bio-inspired design of liquid-repellent structures with enhanced mechanical stability.

(a) Intact structure of interconnected porous surface.

(b) Intact discrete structure.

(c-d) Damaged interconnected structures at (c) 8.6 kPa (kilopascal, the unit of pressure) and (d)11.5 kPa respectively.

(e-f) Damaged discrete structures at (e) 0.4 kPa and (f)2.9 kPa respectively.

Porous surface material just costs about HKD1 per square metre

The research team also developed an innovative microfluidic-droplet-based technique for the fabrication of porous surfaces which is very much similar to shaped-cookies made by baking molds. Here the molds are uniform micron-sized droplets that are produced by microfluidics technology with precise control over their size, structure, and composition. Molded by microfluidic droplets, commercial-scale uniform microstructures are produced at low cost. The material cost is in a range of HKD 0.7 to 1.3 per square metre, only one thousandth of that in purchasing commercialized products such as PTFE water-repellent film. This technique has high accuracy and effectiveness in engineering surface structures, ensured by the precision and controllability of microfluidic-droplet generation that is low in cost and readily scaled up as well.

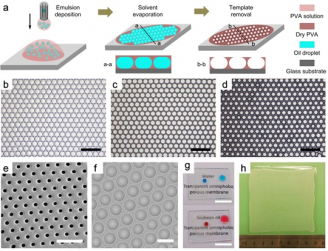

Figure 4 Fabrication of bioinspired liquids-repellent surfaces by microfluidic method.

(a) Process of microfluidic fabrication method, involving emulsion deposition, solvent evaporation, and template removal.

(b) Droplet assemblies after emulsion deposition. (c) Dry film after solvent evaporation.

(d) Porous surface after template removal. (e-f) Images of porous surfaces with different pore sizes.

(g) Transparency of porous surfaces. (h) Wafer-scale fabrication of the porous surface.

The breakthrough will change the way liquid-repellent surfaces are fabricated for robust liquid-repellency, strong mechanical stability, and economical production at a commercial scale. It has also paved the way for further progress in creating surface structures by design, and in tailoring their morphology, repellency and mechanical stability to suit a desired application in various fields, including energy, buildings, automobiles, chemical engineering, electronics, environments, bio-medical industry, advanced manufacturing, water vehicle and military equipment.

For the powerpoint slides on this research, please click here.

For the video clips about this research, please download from the links below:

https://www.dropbox.com/s/hmm4bio9i16hs1x/Liquid%20Repellent%20Fabric%20video%20FINAL.mp4?dl=0 (with subtitile)

https://www.dropbox.com/s/wtdqg172b0h9jec/cut_clean.mp4?dl=0 (clean version)

Media contact:

Department of Mechanical Engineering, Professor Wang Liqiu (Tel: 3917 7908; Email: lqwang@hku.hk)

Department of Mechanical Engineering Dr Zhu Pingan (Tel: 9340 8946; Email: u3002025@connect.hku.hk)

Communication and Public Affairs Office Ms Rhea Leung (Tel: +852 2857 8555/ +852 9022 7446; Email: rhea.leung@hku.hk)

Faculty of Engineering Ms Bonnie Tsang (Tel: 3917 1924; Email bonniepy@hku.hk)