Media

HKU Architecture Lab unveils innovative computational methods for sustainable low-tech timber construction

04 Feb 2024

(From left to right) Chen-Chin Wu, Taichung Branch representative, Forestry and Nature Conservation Agency, MoA; Dr June-Hao Hou, Project Co-investigator, GIA, NYCU; Dr Pei-Hsien Hsu, Director, GIA, NYCU; Nichol Wong Long Hin, Project Lead, BSL, HKU; Chia-Hung Chen, Structural Engineer Representative, A.S studio Engineering Consultant; and Yu-Tung Cheng, Project Research Assistant, NYCU (photo credit: Building Simplexity Lab)

The Building Simplexity Laboratory (BSL), at the Faculty of Architecture of the University of Hong Kong (HKU), has showcased the innovative use of evolutionary algorithms in simplifying non-standard, lightweight catenary wood structures through their design-build project, the KATENARA Pavilion.

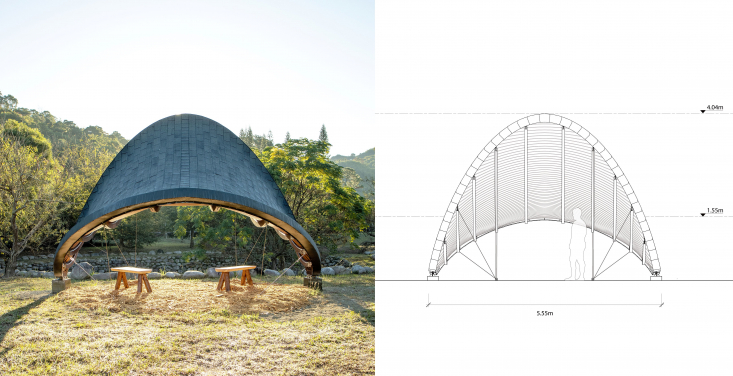

The Pavilion, built in collaboration with NYCU Graduate Institute of Architecture, at Dongshi Forestry Cultural Park, Taichung City, Taiwan, in the fall of 2023, features a striking double-curved wooden roof surface, composed of two glulam ring beams and ten near-catenary-shaped glulam beams, anchored by tension cables. The Project highlights the development of advanced computational methods to reduce construction complexity while emphasising the use of timber as a sustainable, low-carbon construction material.

An exhibition featuring drawings, prototypes, and onsite documentation of the Project - ‘KATENARA: Advanced Computational Methods for Low-Tech Timber Construction’ is currently held at PMQ in Central, Hong Kong until February 16 (Friday). The ‘KATENARA’ exhibition also presents a series of pilot studies and historical precedents to reveal the construction complexities and opportunities inherent in catenary glulam roof systems.

Architects and engineers have long optimised geometry and cost to create structurally sound and visually appealing spaces. Examples include the J.S. Dorton Arena (Matthew Nowicki, USA, 1952), the David S. Ingalls Skating Rink (Eero Saarinen, New Haven, USA, 1958) and the Yoyogi National Stadium (Kenzo Tange, Tokyo, Japan, 1964), all using lightweight suspended steel cables or members as their structural roof system, utilising materials such as concrete, steel, and timber.

Recently, glue-laminated (glulam) timber has gained traction as an eco-friendly option for large-scale roof structures. However, complex glulam geometries are often limited by expensive bespoke moulds.

To overcome this challenge, researchers at BSL developed evolutionary algorithms to reduce moulds, lowering costs and improving accessibility. In the Project, parametric engineering software optimised the catenary beams' number and spacing, while the design was further optimised for low-tech timber construction settings. Japanese Cedar wood, chosen for sustainability and strength, was the primary material used.

Minimising construction costs while maintaining architectural integrity was a primary challenge. The algorithms allowed the pre-fabrication of all curved glulam elements using a single jig, accounting for 19% of the total timber works cost, highlighting the impact of reducing the number of jigs on a project's budget.

Strategically controlled parametric detailing simplified the connection between the roof floor and suspended beams, using steel connection details to facilitate easy fabrication and minimise the complexity of on-site installation. The on-site assembly of KATENARA’s main structure was completed within just three hours.

“The KATENARA Pavilion confirms the validity of the concept and identifies opportunities for future improvements in the design and construction of similar structures. As the first built example of optimised suspended glulam roof structures for low-tech timber construction contexts, KATENARA lays the foundation for more inventive building designs, particularly in developing construction contexts where cost-effective and sustainable solutions are vital,” said Professor Kristof Crolla, Founding Director of BSL.

“The Project showcases how advanced computational methods and evolutionary algorithms can transform architectural design and construction, enabling architects and engineers to create visually striking, structurally efficient, and environmentally sustainable buildings that push global construction boundaries.” Professor Crolla added.

Details of ‘KATENARA: Advanced Computational Methods for Low-Tech Timber Construction’ Exhibition:

Exhibition Period: 19 January 2024 to 16 February 2024

Opening Hours: 11:00am–8:00pm

Venue: H310, 3/F, BLK B, PMQ, Central

Website: https://www.arch.hku.hk/event_/katenara/

For media enquiries, please contact Ms Janice Leung, Faculty of Architecture, HKU (Tel: 3917 5970; email: jan.leung@hku.hk); or Professor Kristof Crolla, Founding Director of Building Simplexity Laboratory, Faculty of Architecture, HKU (Email: kcrolla@hku.hk).

About ‘KATENARA’

The pavilion's English name, ‘KATENARA’, merges the concepts of ‘catenary’ and ‘ara’ to create a distinctive and meaningful title. ‘Catenary’ reflects the pavilion's distinctive curved wooden beams that adopt the natural curve of a freely hanging chain or cable between two points, forming a catenary line. ‘Ara’, a Latin term meaning ‘altar’, ‘sanctuary’, ‘home’, or ‘refuge’, embodies the sense of shelter and solace the pavilion offers as a welcoming space for visitors to relish.

In Chinese, the pavilion's name 弦閣 consists of two characters. ‘弦’ alludes to the shape of hanging lines, found in the catenary-shaped wooden beams, and the elasticity of bowstrings, relating to the steel tension cables that keep the structure balanced. ‘閣’ symbolises a small building or tower designed for leisure, sightseeing, and enjoying panoramic views, offering a serene resting place for visitors amidst picturesque mountains and hills. Combined, they evoke the pavilion's architectural innovation and its function as a tranquil haven for all who visit.

About the Building Simplexity Laboratory

The Building Simplexity Laboratory (BSL), founded by Professor Kristof Crolla, is one of the HKUrbanLabs at the Faculty of Architecture. It questions whether computational design tools can be used differently in contemporary environmentally, socially, and financially sustainable architecture practice, so that onsite affordances can be increased in parallel with the expanding design solution space. BSL also aims to overcome construction complexities associated with digital designs through the simplest of means and in a human-centred construction reality.

The KATENARA Pavilion highlights BSL’s commitment to bridging the gap between digital design tools and construction realities, particularly in developing contexts with limited resources. It explores the innovative methodologies and algorithms employed to create a sustainable, low-tech, and structurally optimised wooden pavilion, made from curved glue-laminated (glulam) timber, illustrating the exciting design opportunities provided by this novel typology. BSL website: https://bsl.hku.hk/